Owner's Manual Version 1

Table of Contents

Important notes for all installations

Note About The Door Placement

Take great care in handling the door/door structure. If the door swings open on its own all the way, it can break the hinges. The hinge may go on either side, so position it next to the wall. The wall keeps the door from falling open all the way.

Since the sides normally bow out and it is better for them to not touch the wall, position the tank 2 1/4 inches (5.7cm) from the closed wall.

Warm Salt Before Use

The salt should be as warm as possible before it is put in the tank. So bring it in out of the cold if appropriate. The water that you put in the tank should be as hot as possible. If you are comfortable adjusting the temperature of your hot water heater turn it up at least 1 hour before you plan on filling the tank. And, don't forget to turn back to standard when you are done.

Warning: Sharp Crystals

Please note, when draining or refilling or moving the tank, the solution can dry in a very sharp needle like form. So be obsessive compulsive to make sure not to get any of it between the liner and the tank or wash very thoroughly. Otherwise it can puncture the liner and cause leaks.

Environmental Conditions

The tank is not designed to be installed outside or in bright indirect sunlight. These conditions age the plastic unnecessarily.

Receiving Shipment

Checking Your Shipment

Visit the link below for instructions on checking your shipment.

Instructions for checking your shipment.(READ)

Please read before receiving shipment

Receiving shipment on pallet

Keep plywood if you have optional sound isolators or optional speakers.

Sound Isolators

Sound Isolators Step 1

Adhere sound isolators on a 1" piece (or two 1/2" pieces glued and screwed together) of plywood 41 3/4" by 90 3/8" (2.5 x 106 x 229 cm.)

Sound Isolators Step 2

Center row - 44" and 20" (111 and 51cm.) from each end. Side rows are 8" (20cm.) from each side and 8" and 32" (20 and 81cm.) from each end.

Sound Isolators Step3

Position it where tank is to be placed, then turn it over. Place the bottom on the plywood.

Transducers

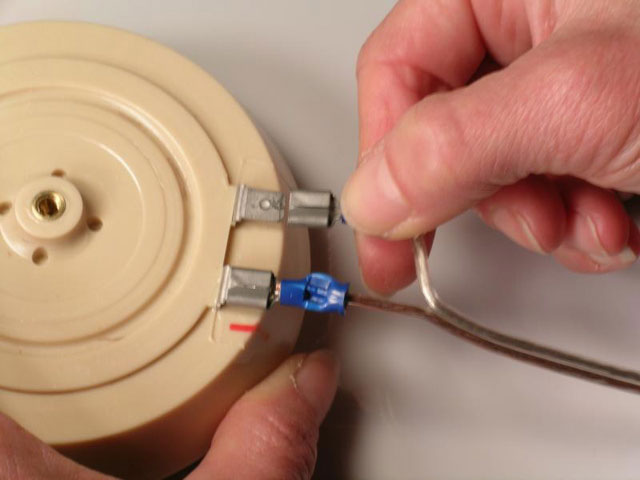

Transducers (Speakers) Step 1

Slide connecting terminals onto transducers(like speakers).

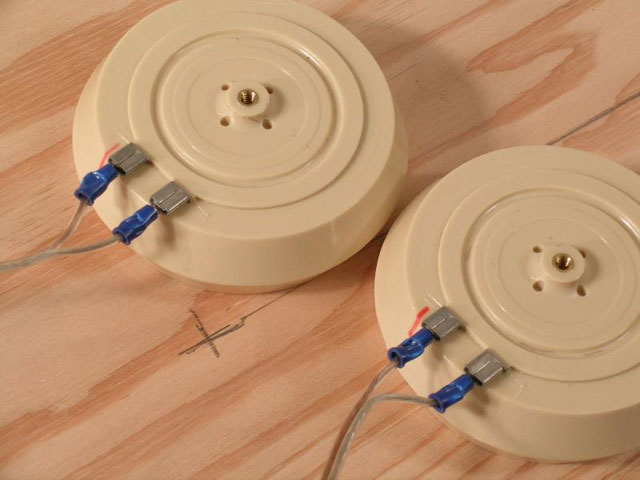

Transducers (Speakers) Step 2

Ready to attach to the under side of the bottom.

Transducers (Speakers) Step 3

Screw carefully onto the front bolt of the bottom. Not too tight, barely snug.

Transducers (Speakers) Step 4

One in place. Now do the other.

Transducers (Speakers) Step 5

Run the wire to the back and tape in place.

Body of Tank

Locate your bottom where you want your tank to be. The underside of the bottom at the rear has an oval recess. The hinge needs to be close to the wall, so that the door, when open, can rest against the wall. The door MUST be supported to protect the hinges.

Left side.

Bottom of side sets down onto rail.

Another view of the left side being set onto the bottom.

Left side in place.

Right side.

Right side in place.

Front.

Front.

Front.

Front hook into side slot.

Front in place. May have to push down with all of your weight, to get it down. Same with the back.

Back.

Heater and Control Sensor

Heater (may be a different model).

Heater centered over white plastic.

Heater should be even, not like this.

Tape the header cord in place.

And here.

If you have the optional digital

temperature control insert it's sensor. Do not plug the heater into

it until the tank is filled and NO SALT is on the heater.

Heater cord goes out through the bottom center hole in back, closest to the wall (wall on left). Photo doesn't show tank bottom.

Sensor comes in (on right).

Remove backing from double faced tape.

Attach snugs to outside of back. Put heater cord on side closest wall, sensor away from wall.

Heater cord comes out , sensor wire (in this case, white) goes in.

Light

Light Step 1

Push the light lens through one of the lower outside holes in back.

Light Step 2

Screw nut on the outside.

Light Step 3

Slide light reflector with bulb on the outside.

Light Step 4

Light.

Light Step 5

Remove protective backing from double faced tape.

Light Step 6

Adhere light cover over light.

Light Step 7

Wire comes out groove.

Floater Comfort Control

FCC Step 1

Floater comfort control.

FCC Step 2

Install buzzer of floater comfort control in a thru the wall fitting in one of the outer bottom two holes.

FCC Step 3

Plug the power cord into the back of the top and into the Floater Comfort Control (FCC) or if you do not have the FCC then into power. If you have the FCC, learn more at Floater Comfort Control.

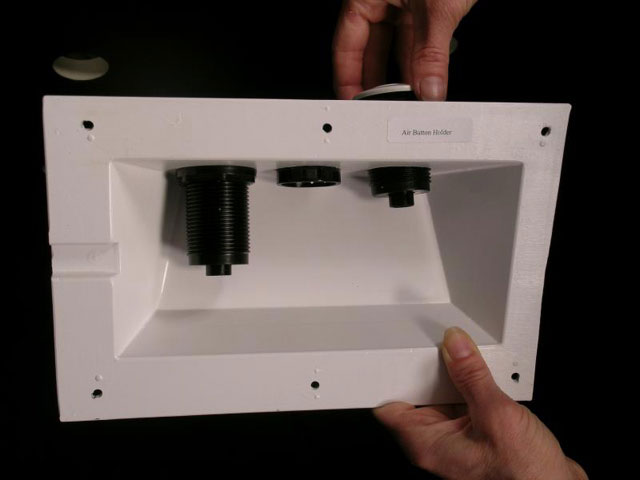

Air Button Holder

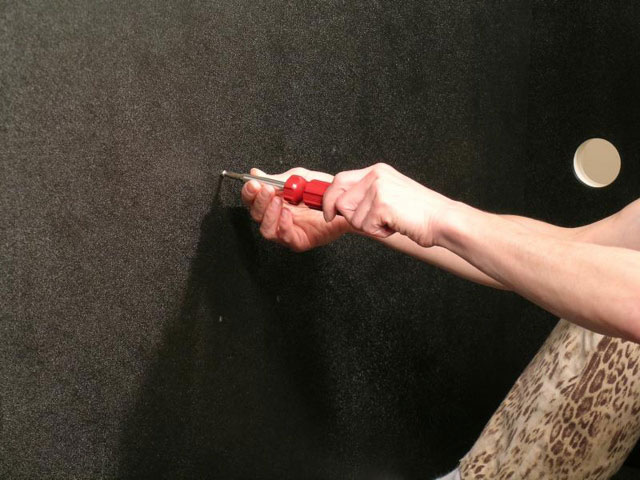

Air switches such as the light and the floater comfort control have an air button holder screwed to the inside of the left wall of the tank.

Remove the screws from their holes.

Save screws for later.

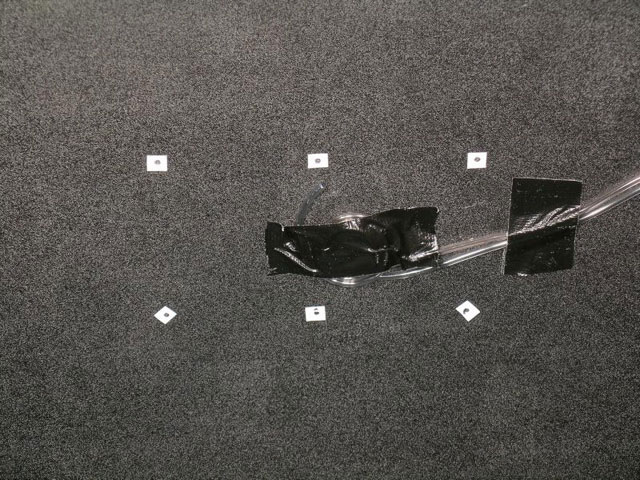

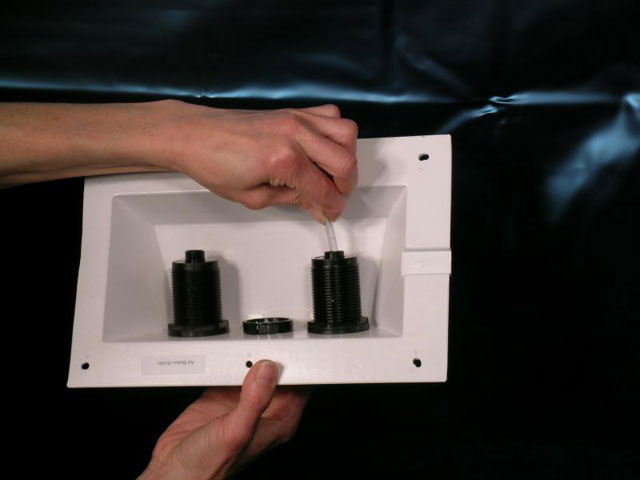

For each air switch, put a rubber tube into little hole in back (since photo, holes have moved to edge of back).

Attach clear tube to rubber tube inside hole. Run clear tube to center of 6 holes and tape in place. Be sure tube is exactly in the center of the right 2 screw holes.

Here tube needs to be slightly higher to be centered between right holes.

Insert Canoe Clips

The three 1/4" (.6cm) holes in the back, near the left side, need these canoe clips in the holes from the inside, except for the ones that have tubes in them for the optional light or floater comfort control.

Cover Holes with Black Squares

Some options use the holes in the back that are at the bottom outside. Put black plastic squares over the inside of those holes not used by options.

Liner

For correct liner fit, put toes in corner.

Toe holds liner in corner.

Hold corner in place and pull the liner up.

U channel holds liner in place and goes on the inner protrusion.

NOT THIS WAY on outer protrusion.

Start at the end, pushing down as you go, until you get to the other end.

Cut liner just outside inner protrusion.

Air Button Holder (continued)

After installing liner, cut a small hole in middle of 6 screw holes.

Pull clear tube through hole.

Install air buttons into holder.

Install air buttons into holder.

Cut clear tubes about 1' (.3m) beyond liner slit and attach tube to air button.

Screw the holder in place locating it against the guides.

Filtration System Fittings

Liner in place. Next cut holes. Bottom 4 holes do NOT have liner cut, because they are below water level (note that the bottom outer holes often have black squares covering them). Cut only the middle and top holes. (Also one top hole isn't cut for two way communication.)

Pie cuts, 1/2" from edge of hole to center.

Discharge.

Through left middle hole.

Screw nut on the outside.

Screw the grey angle on.

Suction.

Skimmer.

In the right middle hole.

Through the wall fitting (TTWF) for air in (center hole).

Same for the top 2 holes (labeled air out and options). Be sure to screw on their nuts.

Door and Door Structure

Door structure, hinge near wall. (Take care that the door doesn't accidentally swing open). Set bottom of door structure in place first.

It may not fit down all of the way on the front if the sides are too close to each other. So push the door structure back (at the bottom of it) and then down over the front.

Structure being set in place. Open the door and reach inside and run your fingers between where they connect. If there is any question whether it is seated down on the front, push the sides out from inside and then repeat pushing the structure back and then down until it is in place.

Lift top of door structure so the front of the top will go into place. Door structure down, lift front of top, top forward, and then down in back. If this doesn't work easily, put top down in place including at the back and try the following. Rest your weight on the top of the door structure (like person’s left hand is placed) and with the other hand give a sharp upward blow underneath the top at the front.

Putting your hand through the door opening, check inside where the door structure meets the top to insure that they meet well with no gap. If there is a gap, retrace your steps until you are successful. There should be very little black showing at the corners of the structure on the front and top and also on the back below the top. Then with the screws provided in the largest shipping container screw the corners of the structure to the top and front. The holes drilled should line up. Then do the same in the back under the top.

Attach the power cord supplied to the back of the top and plug it into power or into the floater comfort control if you have that option. This prevents condensation.

Since the underside of the top is being heated to prevent condensation, the under side of the top expands, resulting in the middle of it sagging a small amount.

Stills

Still bottom is closest to the viewer.

Installing still in the through the wall fitting (TTWF) labeled air out.

Second still in the center TTWF labeled air in.

Filling the Tank

Add 1/2" to 3/4" (1 to 1.5cm) of warm water.

Smooth out the liner.

Get all of the wrinkles out.

Start adding 700 pounds (360kg) of epsom salt. Add as hot water as you can into the center of the salt pile. Stop for an hour when it starts to not be very hot.

When all of the salt is in and the solution is 10" (25cm) deep, stop the water, get in, and mix the salt. Do NOT leave any salt on the heater or near the suction pipe.

Adjusting the Solution Temperature

Once the tank is filled and salt is off the heater, plug the heater into the digital temperature control.

Digital temperature control. The top display shows the solution temperature, assuming the sensor is touching the liner in back.

The lower display you set to whatever you want the temperature in the tank to be. 93.5 may not be the correct temperature, but it is a good place to start. Adjust it to your comfort.

If, when you float, you are too cold, the set temperature needs to be higher, so press the up button. Wait at least half a day, float and adjust it again.

If you are too hot when you float, lower the temperature by pressing the down button. Repeat the whole process until the temperature is exactly comfortable for you.

Filtration System

The Pump may look like this OR

this OR something else. Strainer basket on right.

One possible version of the filter .

Another version of the filter.

Pump stand goes under the pump on the shallow tray.

The complete filtration system may look like similar to this, unless you have the ozonator.

Filtration system with optional ozonator looks similar tto this.

To be put on the pump before the filter .

Slide the tube on the fitting on the top of the pump. Clamp.

Slide the tubing onto the fitting this far.

NOT this far .

If you ever have to remove it like this, it is hard to do if on too far.

On just far enough to tighten the clamp .

Slide the fitting onto the tube entering the filter. Clamp.

Attach to the outlet fittings and tubes coming from the filter outlet.

Be sure to clamp it well.

Ozonator (Optional)

Ozonator Step #1

For optional ozonator, attach short piece of clear tubing and clamp it.

Ozonator Step #2

Ozonator manifold is directional. As shown, the filter is to the left.

Ozonator Step #3

Attach it to the short clear tube and clamp it.

Ozonator Step #4

Attach the hose to the output of the manifold and clamp it.

Ozonator Step #5

Complete filtration system with ozonator.

Ozonator Step #6

The ozonator with the tube attached.

Ozonator Step #7

Tube attaches to the outlet, nothing to the inlet. Inlet allows air in to be ozonated.

Ozonator Step #8

Attach other end of tube to the manifold.

Ozonator Step #9

Place ozonator on wall with tube sloping down.

Ozonator Step #10

Complete with hoses attached.

Ozonator Step #11

and ozonator hanging on wall.

Filtration System (cont.)

If there is no ozonator, attach a hose to elbow below stainless pipe and to pump inlet.

With the filtration complete, attach the hoses to the back of the tank.

Hose from pump goes to the suction pipe.

Attach the grounding clamp to the stainless steel nipple.

Plug it into a grounded outlet or attach to a grounded metal pipe or run wire outside and attach to a stake in the ground where the ground stays moist.

Priming the Pump

Always prior to opening the pump, release air pressure on the filter. Wait 1 minute and then close it snuggly not too tight.

Releasing the air pressure on a different filter. Note that by unscrewing the large knob on top of the filter, allows you to open the filter and remove the element.

In order to prime the pump, first open the strainer basket of the pump.

By turning ring counter clockwise.

Remove the media temporarily.

Fill strainer basket full with water.

Close strainer top, and check all clamps and fittings prior to turning on the pump.

Make sure filter top is on.

Prior to starting pump, close the air relief valve on the filter. Snug but not too tight.

And check all clamps and fittings prior to turning on the pump.

Plug it in. Let it run a few minutes.

If it does not start in one minute, turn it off and refill basket to top with water, close and try again.

Adding Diatomite

Open the filter air relief valve, wait a minute, open the pump strainer basket lid and close the air relief valve again. Add 6 cups of diatomite(all of the box) to the open strainer basket. NOTE that tanks exported from the United States do not have included diatomite, as it seriously confuses the customs people in many places. See if you can get diatomaceous earth locally.

Adding diatomite, use care. Don't breathe it. It is dusty.

Close strainer basket.

The air release valve is snug but not too tight. Plug in the pump and run a few minutes.

Go through the whole process again of releasing air from the filter and opening the strainer basket. Then insert the media to below the flap. Close it all up and you are in business.

Timing and Digital Alarm

Timing & Digital Alarm Step 1

Professional timing system and digital alarm. These are discussed together since they are so interrelated. If you don't have the optional alarm you will use instead a cd player or some other sound making device that will go on and off when you plug and unplug it.Timing & Digital Alarm Step 2

Do not change the settings on any of the equipment without talking to us at Samadhi. But do look over the remote/timing controls to understand the two remote switches (low watt appliance module and the high watt switch). Please read all instructions prior to doing anything.These are X10 devices. They send signals back and forth between units on the circuits of your building. NOTE that the power strips used for X10 can NOT have surge proection.

Timing & Digital Alarm Step 3

First plug in the low watt appliance module. Don't change it's house and unit settings (it should be on 9). Plug your sound generator or the digital alarm if you have it into the low watt switch.

Timing & Digital Alarm Step 4

Plug the high watt switch into power and the pump and ozonator into it. Unit code should be on 10

Timing & Digital Alarm Step 5

Plug the Wireless receiver into the power.

Timing & Digital Alarm Step 6

Plug the program module into the power. This device has the programs in it that allow a sequence of events to happen with the push of one button. It has the programs in it that we would and have used renting out tanks. If you want different programs, you can connect it to a computer and, using the included cds, make different programs tailored to your needs.

Timing & Digital Alarm Step 7

Professional timing system set up. High watt switch is back left. Wireless receiver is next to the right with the aerial. Low watt switch is next to the right with a cord from a sound source coming to it. The program module is on the right end of the power strip. And wireless controller is front right. Now to use.

Timing & Digital Alarm Step 8

Confirm that the house code of the small wireless controller is the same as the remote switches(both low and high watt).

Timing & Digital Alarm Step 9

You may control not 8 but 16 remote switches with the wireless controller by sliding this to the left for 1-8 and right for 9-16. One of these buttons will control either an electrical device via a remote switch or a program that may consist of turning on and off at different times, several switches and their corresponding devices. In this case, 9 through 16 are used for the remote switches and their electrical devices and 1 through 8 are used to trigger (or initiate) programs stored in the program module.

Timing & Digital Alarm Step 10

If the slide is to the right, switch 9 turns on and off the alarm, switch 10 turns on and off the filtration system. With the slide to the left, the programs can be activated. Pressing switch "1 on" initiates a 1 hour float. The program times 1 hour. The alarm goes on for 2 minutes and then off and then the filtration system goes on for 15 minutes and then off.

Timing & Digital Alarm Step 11

Pressing switch "2 on" initiates a 1.5 hour float. At the end, a 2 minute alarm and then a 15 minute filtration. You should press the "off" button after initiating each program, so that it is ready to be initiated again. "Off" doesn't cancel a program .

Timing & Digital Alarm Step 12

Switch "3 on" initiates a 2 hour float. Then the 2 minute signal and the 15 minute filtration.

Timing & Digital Alarm Step 13

Switch "5 on" initiates the filtration system for 15 minutes and turns it off.

Timing & Digital Alarm Step 14

Switch "6 on" for a 1 hour filtration.

Timing & Digital Alarm Step 15

Switch "8 on" turns the alarm and the filtration system on and then off after 1 minute.

Timing & Digital Alarm Step 16

The digital alarm is a 20 second recorder. Each time it is plugged into power it outputs 20 seconds of sound. To replace the 20 seconds of sound, hold down the white button (with a ball point pen etc) for 20 seconds. The microphone is the little dark button. You may want to gradually increase the volume over the 20 seconds. Then unplug it and plug it in to see how you did. Experiment to see what gives the best results.

This is used for tasks like draining the tank. It is not part of the assembly process. I suggest leaving it in the tray that the filtration system sits in.

Remote Timing and Control

These are X10 devices. They send signals back and forth between units on the electrical circuits of your building. NOTE that the power strips used for X10 can NOT have surge proection. This unit is a switch and will switch power on to a device that is plugged into it.

High watt remote switch. This will do the same thing and will switch a larger device on, such as the pump.

This is the controller that is used to control the remote switches in the previous 2 photos.

Plug the appliance module (low watt remote switch) in and notice the house code. Leave as is unless you find someone in your building is already using that letter.

Keep the house code to the same letter. All units you have need to be set to the same house code.

The house code on the controller.

Leave the unit code on the low watt appliance module to 1. Plug an electrical device into the module and the module into an electrical receptacle.

Unit code to 2. Plug it into your power and the pump and optional ozonator(if you have it) into it.

The filtration system into it.

Press unit 1 switch on. The device plugged into switch 1(the low watt appliance module) should go on.

Press switch 1 off. Device should turn off. This control unit often is able to be on any outlet in your building.

Press switch 2 on. The pump should go on.

Turn the pump off.

Motor Protector

Plug the pump into the motor starter(protector) and the motor starter into the power(AC) or if you have it the high watt switch.